We work based

on sharp values.

|

|

Motivated employeesThrough ongoing education and motivating activities, we ensure that all employees are consciously working to do things right the first time. At HST, we consider it important that all employees also collaborate across the organization, thereby achieving greater professional and personal development. |

|

|

ISO 9001:2015 & ISO 14001:2015We are ISO certified in both quality management and environmental management, and we are proud to maintain this certification every year. |

|

|

Deliveries of both large and small series.At HST we have a very wide customer base, which means we often have to adapt our production. But this also means that we have great expertise in both one-piece items as well as series production. |

|

|

Delivery reliabilityAt HST, we always strive to deliver what you order without any errors or deficiencies. We achieve this by having high-quality assurance before we ship your items. |

|

|

EfficiencyWith a production that makes both large and small series, we always strive to deliver on time as agreed. |

|

|

Flexibility in all areas.We want to be recognized as an efficient business partner with a wide range of manufacturing processes that solve the user's process problems or significantly contribute to their competitiveness and earnings potential. Quality requirements and goals are set accordingly. We want to be known and sought after as an efficient supplier whose quality and prices meet the expectations and needs of our customers. |

We collaborate with

Big Science.

BigScience.dk serves as the link between the Danish business community and the larger European research facilities (Big Science facilities) of which Denmark is a member.

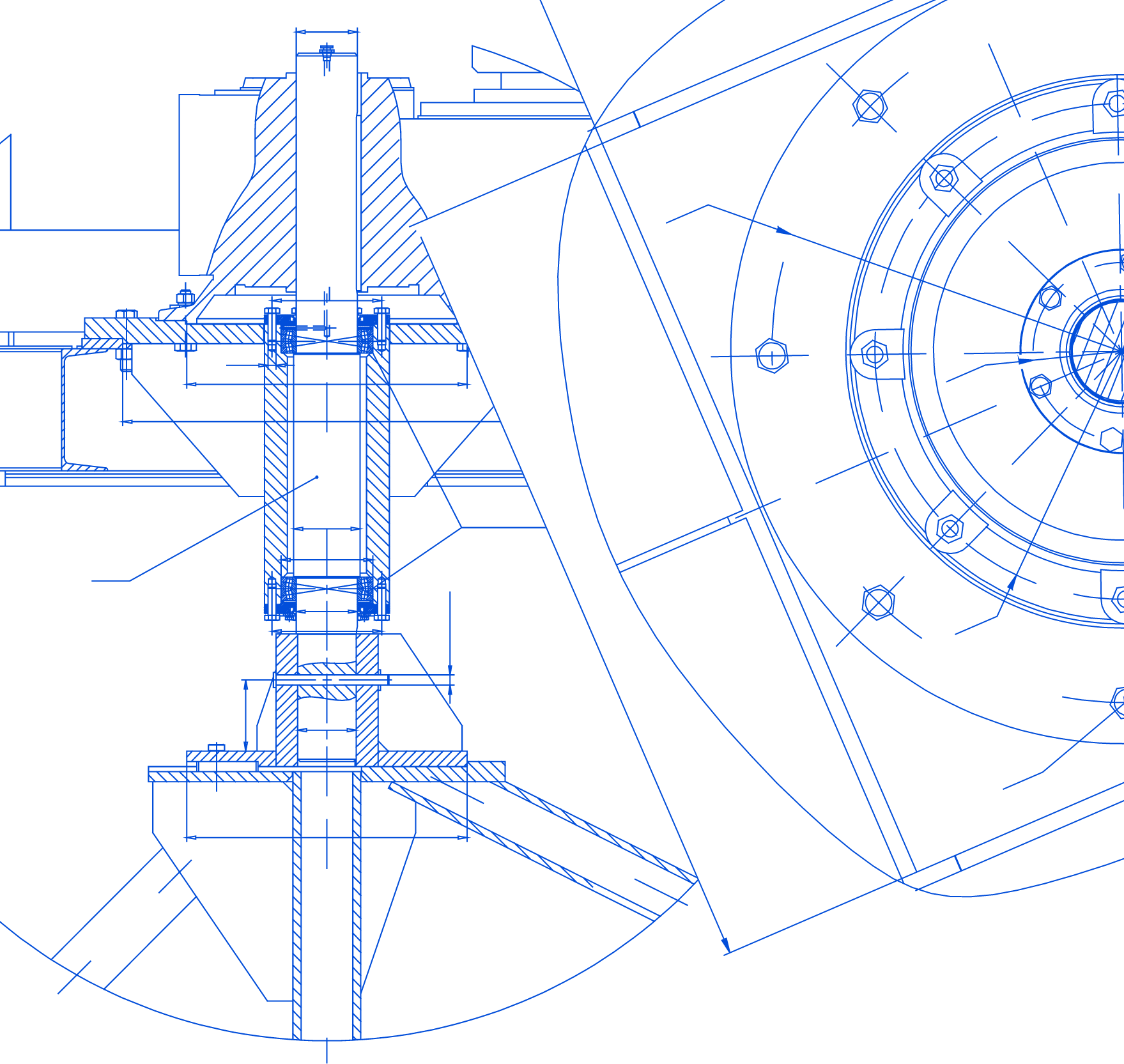

The CAD systems are

always up to date

To support file handling from our customers' CAD systems, we have annual updates of GibbsCAM for programming our machining centers with 4 axes and full utilization of palettes as well as lathes with up to 5 axes.

These measures increase the company's ability to adapt, allowing us to quickly adjust to new productions while ensuring top quality.

The GibbsCAM software ensures that the components we deliver match 100% with the customer's requirements based on the CAD drawings. Together with our skilled employees, it ensures fast and secure delivery for you.